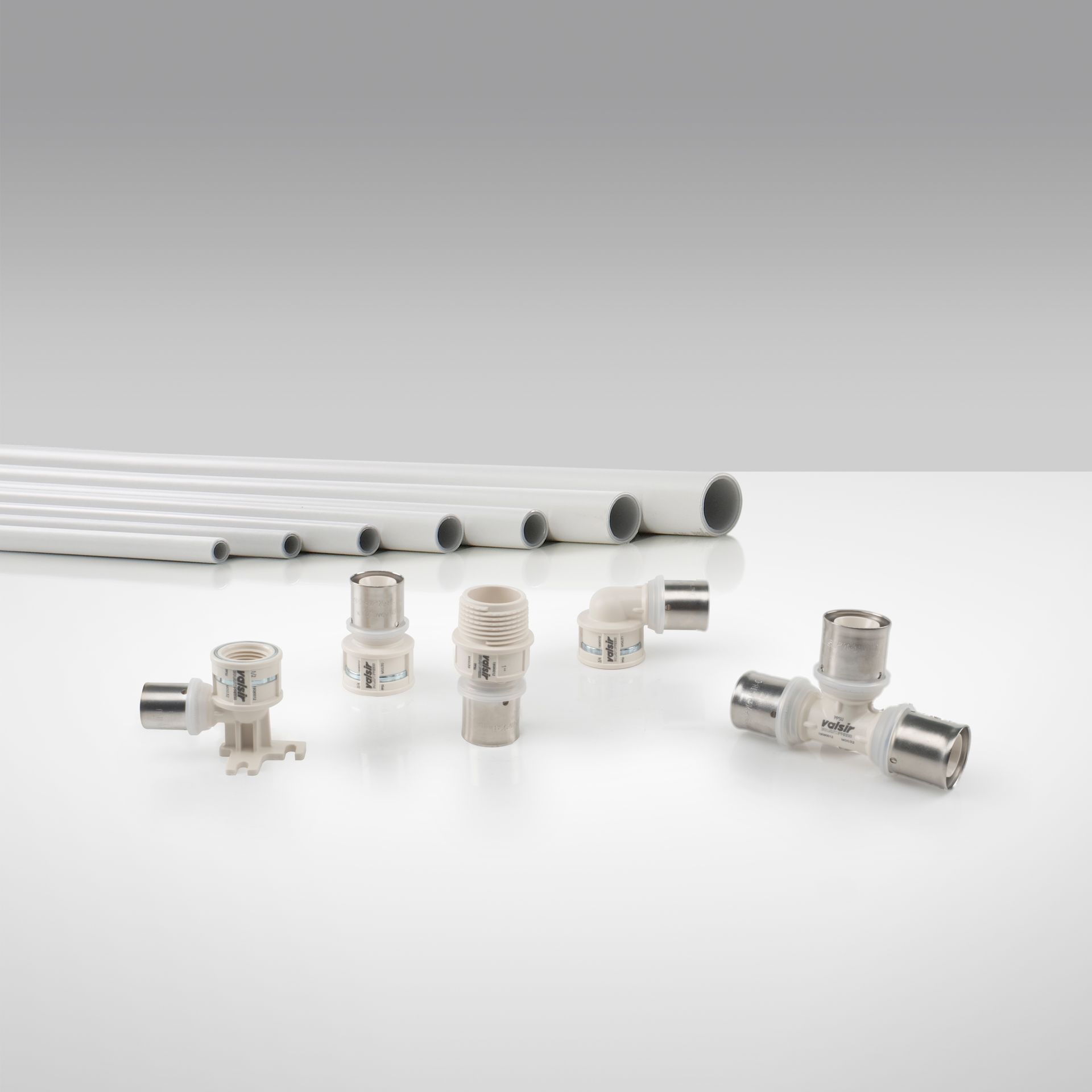

Bravopress® is a WRAS approved press fittings system made of technopolymer (PPSU), a plastic material characterised by an exceptional mechanical and corrosion resistance. Bravopress® can be used with Pexal® and Mixal® multilayer pipes and can be employed for the construction of water supply, heating and cooling and industrial systems.

The Bravopress® Difference.

The Advantages Of Press Fittings In Technopolymer:

- Total absence of oxidation and corrosion.

- Compatibility with a wide range of pressing profiles (H, TH, U, C, VAL).

- WRAS Certification for the transportation of drinking water.

- Chemical resistance to the most common substances dissolved in water.

- Range of diameters from 16 to 63 mm.

- Extremely lightweight.

- Leakage detection during system testing in the event of incomplete pressing on diameters from 16 mm to 32 mm (for leaking test pressure between 0.5 and 2 bar).

- Greater control of insertion of the pipe on the fitting thanks to the transparent base ring and the holes on the sleeve.

- High resistance against legionella with thermal or hypochlorite treatment.

- Made of Polyphenylsulfone (PPSU) is a technopolymer that provides exceptional mechanical performance.

Polyphenylsulfone

Bravopress is made of Polyphenylsulfone (PPSU)a technopolymer that provides exceptional mechanical performance, used mainly in automotive applications, in the aerospace and medical industry, and which in recent years is now widely used in the plumbing industry.

This material stands out for its excellent mechanical resistance even at high temperatures and its resistance to the main chemical compounds. The mechanical characteristics such as tensile strength, modulus of elasticity and ageing resistance far exceeds those of normal polymers.

Characteristics

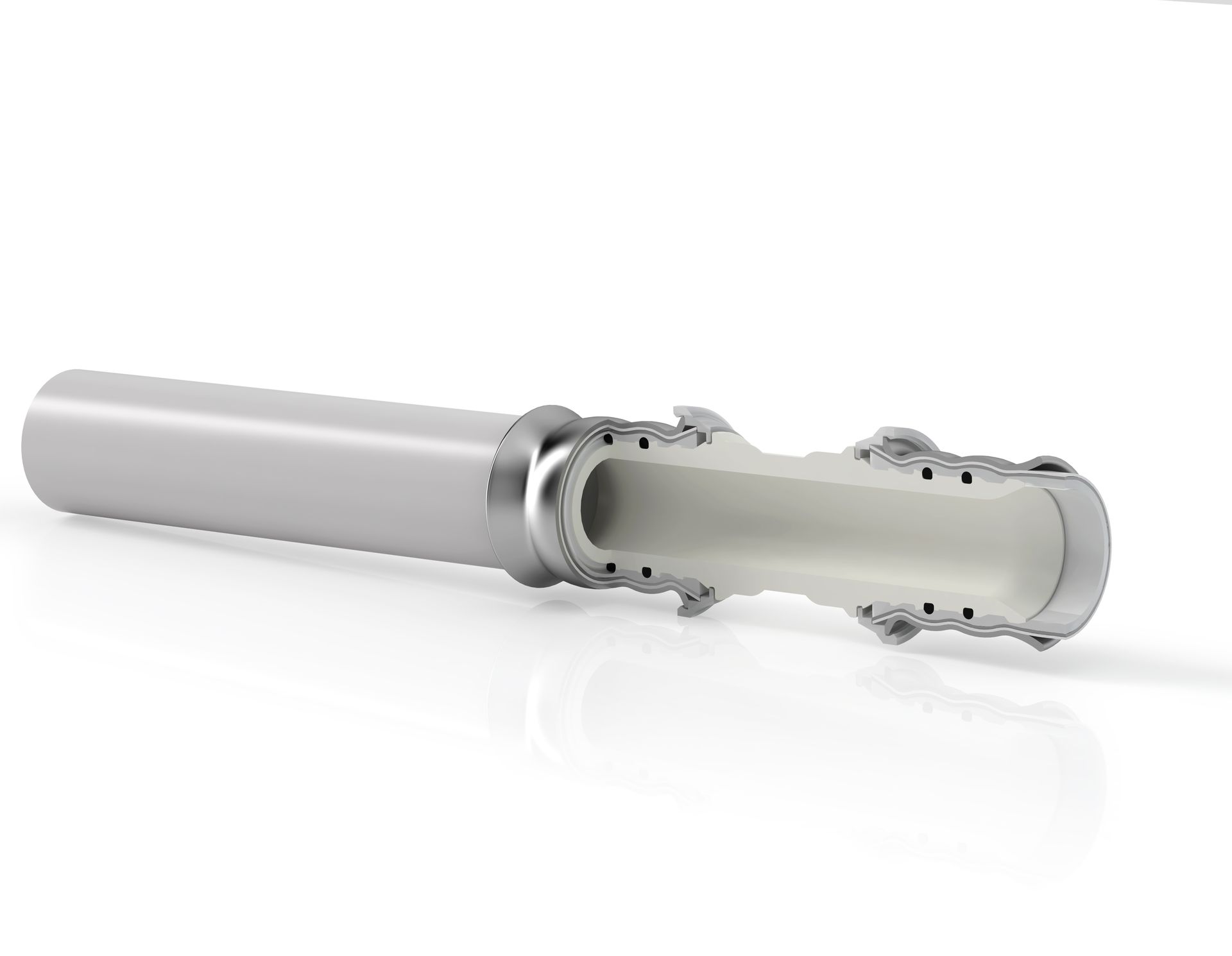

The Bravopress® line of fittings combines the exceptional mechanical characteristics of polyphenylsulfone with the advantages of a pressed joint with stainless steel sleeve.

Just like the brass press fittings, Bravopress® line was designed to reduce installation times by using a portable pressing machine equipped with specific pressing jaws.

The insert of these fittings, equipped with two O-rings is characterised by a special profile which, in the event of a non-pressed fitting, allows the immediate identification of the leakage by dripping during pressure testing of the system.