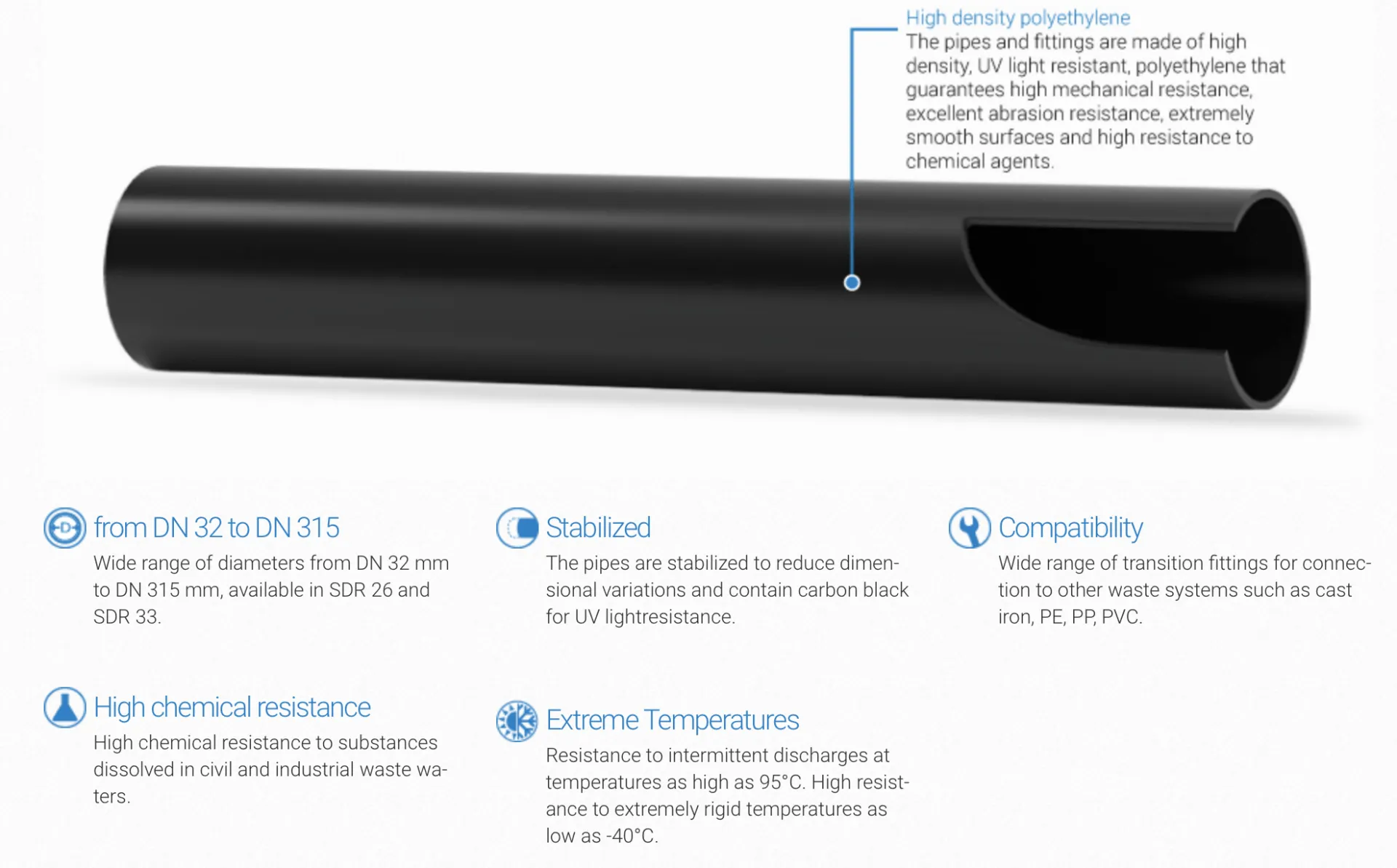

Valsir HDPE is a fusion welded system made up of pipes, fittings and accessories, suitable for all installation types, destined to waste and rainwater drainage. Valsir HDPE is produced in compliance with European Standard EN 1519 and can be used in waste systems at low (as low as -40°C) and high temperatures (up to +95°C), in ventilation systems of waste networks and for rainwater drainage inside civil and industrial buildings, hotels, hospitals and laboratories thanks to its high resistance to chemical compounds. The wide range of pipes, fittings and accessories allows a complete waste system to be constructed, from the branches of the sanitary fixtures, to the soil stacks and soil manifold. Just take a look at the difference specifying, choosing and installing Valsir's HDPE® can make:

- Wide range of diameters from Ø 32 mm to Ø 315 mm, available in SDR 26 and SDR 33.

- The pipes are stabilized to reduce dimensional variations and contain carbon black for UV light resistance.

- Possibility of prefabrication to reduce assembly time on-site and possibility of creating special pieces for particular applications and solutions.

- High chemical resistance to substances dissolved in civil and industrial wastewater.

- Resistance to intermittent discharges at temperatures as high as 95°C.

- High resistance to extremely rigid temperatures as low as -40°C.

- Excellent abrasion resistance and mechanical strength.

- Highly versatile and easily installed thanks to its light weight and numerous connection methods that allow wastage to be reduced to a minimum.

- Wide range of transition fittings for connection to other waste systems such as cast iron, PE, PP, PVC.

- The product, its total recyclability and the production processes used are all based on the Green Building principles, respecting the environment and conserving resources.

- Extensive stock availability from our central stock-holding with daily deliveries across Ireland and Northern Ireland.

The HDPE Difference.

All Valsir HDPE pipes are stabilized to eliminate residual tensions caused by the production process and to reduce dimensional variations.

SUSTAINABILITY - SGBC & EPD

HDPE is completely recyclable and designed according to the principles of Green Building. Just like our Triplus, HDPE is the only drainage system in the world to be awarded the VERY GOOD rating (double tick) by the prestigious Green Building Council of Singapore.

This certification highlights the very high level of sustainability of HDPE production process; thanks to an extremely careful management of energy, raw materials, water, and waste within a plant that is also certified to ISO 9001, 14001 and 50001 standards, HDPE is one of the most sustainable drainage systems on the market.

The EPD statement is available on REQUEST to certify the reduced environmental impact associated with HDPE according to the full life cycle assessment, or "cradle to grave". This means that our monitoring and optimization efforts do not only cover the production stages: HDPE is a champion of sustainability from the extraction of its raw materials to the disposal of the product itself. Choose it for your project and get credits for Green Procurement sustainability protocols.

HDPE Jointing

Manual Butt-Welding

Thanks to the extremely light weight of polyethylene, pipes and/or fittings up to a 63 mm diameter can be butt-welded using a manual process which involves the use of a heating plate only. It’s an extremely convenient jointing method on site.

Machine Butt-Welding

Valsir supplies butt-welding machines that weld up to 315 mm diameters. This process is extremely useful for the prefabrication of system parts that are then installed and connected on site using the other numerous jointing methods, such as welding with electrofusion sleeves.

Electrofusion Couplings

Thanks to the use of electrofusion couplers that are available in 40 mm diameters to 315 mm diameters, all system parts can be prepared. Valsir supplies two types of welding machines that guarantee rapid, uncomplicated and extremely reliable welding.